It is becoming clear that outside of basic machine operation post processors requirements can be incredibly varied. In my opinion, you are leaving a lot of money on the table by hand editing programs.I am not hand editing anything. In my opinion, you are leaving a lot of money on the table by hand editing programs. From our 3 and 4 axis verticals and horizontals in Mastercam to our full 5 axis mill turns, to our 3 turret, two spindle, 13 axis Swiss machines in Partmaker (now part of Featurecam). Every single program we generate is post and play. We as a practice, do not touch programs by hand.

Camworks post processors how to#

Really, if you know how to edit and/or make posts, the sky is the limit. Can you provide examples of post processor modifications that truly make a significant difference? Thanks, -MartinHow about full integration of all of the Renishaw Productivity+ Probe macros? Via custom drill cycles in Mastercam. Another it has no impact on whether a part is made correctly or not. While it might make code more readable for one person vs. Line numbers, comments are trivial issues. I'd like to learn more about what people are doing that might be so different.

Camworks post processors manual#

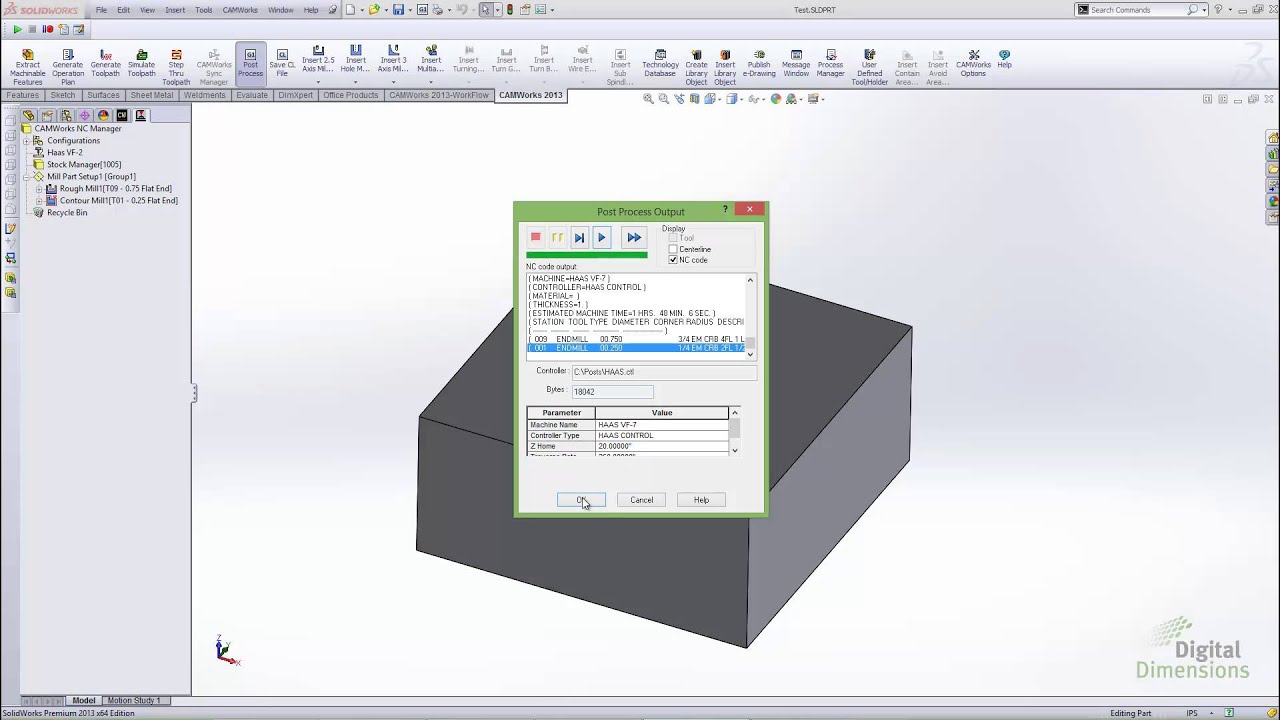

Their basic function is to translate the toolpath you see on screen to machine-readable code (often referred to as G-code), but with the right post processor you can reduce machine cycle time, remove manual editing and provide more information to your operators for a faster setup time. Post processors are a critical part of any CAM system. SOLIDWORKS CAM & CAMWORKS POST PROCESSORS. This course will teach users how to write their own post processers for use with CAMWorks.

0 kommentar(er)

0 kommentar(er)